BetaAndon

Realtime Web Andon

WHAT IS BetaAndon?

Andon is a manufacturing system that informs operators involved in management, maintenance and other tasks of the presence of a quality or process problem.

The main component is a display board, an andon panel, which incorporates light signals indicating which station has the problem.

The andon panel is one of the main components of the quality control system according to the autonomy concept that is part of the so-called lean manufacturing approach.

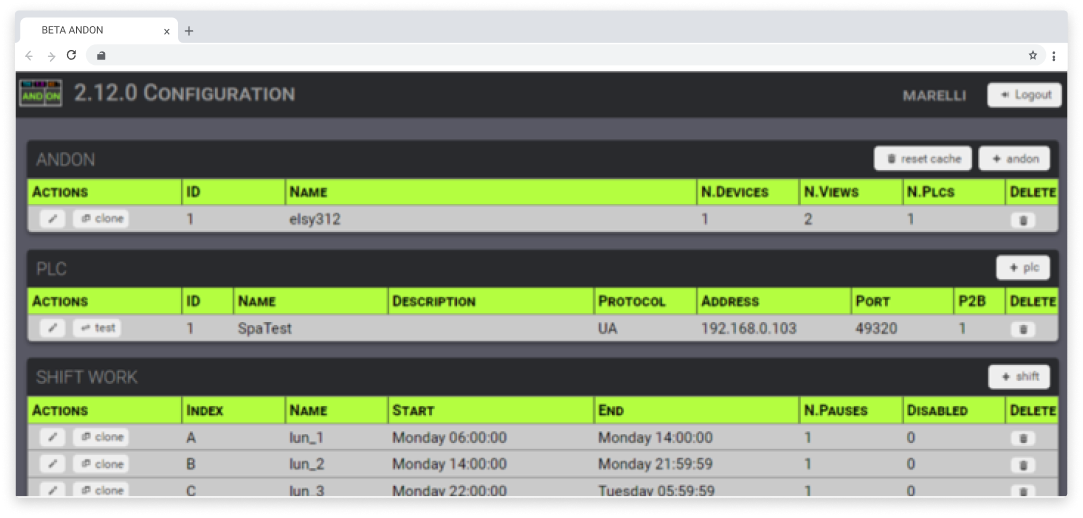

BetaAndon is a software implementing a web viewer that can be configured according to requirements. It is possible to configure the table structure to be displayed on the andon board through a simple graphic interface. BetaAndon is multi-platform and can therefore be easily installed on any device and operating system.

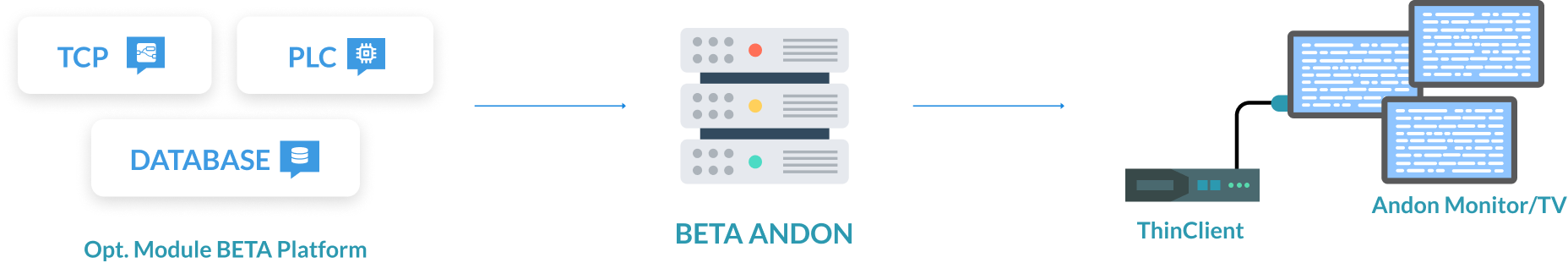

After installation, our Andon system is ready to set the parameters for receiving and sending data to the various display interfaces. The system is able to receive data from TCP, PLC or database sources.

NEW ANDONS CONFIGURABLE VIA WEB INTERFACE

POSSIBILITY OF CLONING THE ANDON

CUSTOMISABLE UI

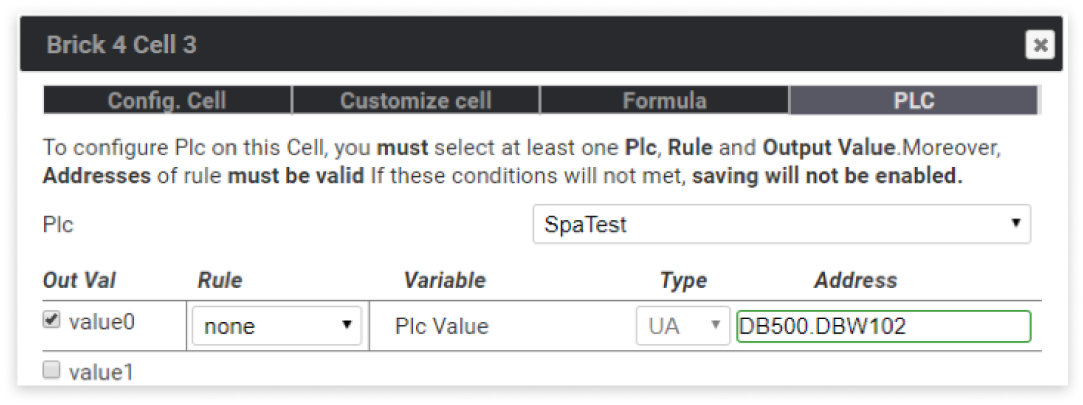

PLC INTERFACE VIA SIEMENS S7, OPC UA

MULTILINGUAL CONFIGURATION

REAL TIME NOTIFICATIONS

Strengths

Web, client/server architecture developed in Node.js

PLC interface via SIEMENS S7, OPC UA

Support for integration with JSON-formatted data via TCP protocol

Data transformation/formalisation via dynamic source code written in Javascript, configurable via web interface

Possibility to integrate BETA Platform modules for data input in TXT, CSV, etc. format.

Multi-language configuration. Ability to use up to three languages.

New Andons can be configured from the BackOffice web interface

UI customizable with 4 themes, customizable for each cell

Possibility to clone the full Andon or a single row with offset adding functionality to input data structures

Front-end interface usable from web browser (IE, Chrome) on Thin Clients, Industrial PCs and Desktops

Real-time notifications via Node.js Socket.io module

Fully functional installations at our customers’ offices and plants worldwide

DEVELOPED WITH THE BEST TECHNOLOGIES

FRONTEND

The frontend configuration uses the jQuery library and the formatting languages CSS3 and HTML5. The interface is responsive and therefore adapts to any type of device. Through the use of Socket.IO, the data displayed are updated in real time.

BACKEND

The server uses Node.js and relies on a MySQL database in order to collect all input data. A TPC server is activated in addition to the web server by listening for packets arriving on the channel.

MODULI

The list of input data sources includes: TCP, PLC and database.

MORE INFO?

Or do you need a tailor-made solution?

More about our software.

We will be happy to advise you on the most suitable solutions for your company’s needs, answering any doubts or questions, or scheduling a guided demo to show you the functioning of our software.

We provide our services throughout the country.

Betacom staff is at your disposal:

fill in the form and we will contact you.