BETA3A

Software for managing anomalies and monitoring production.

WHAT IS BETA3A?

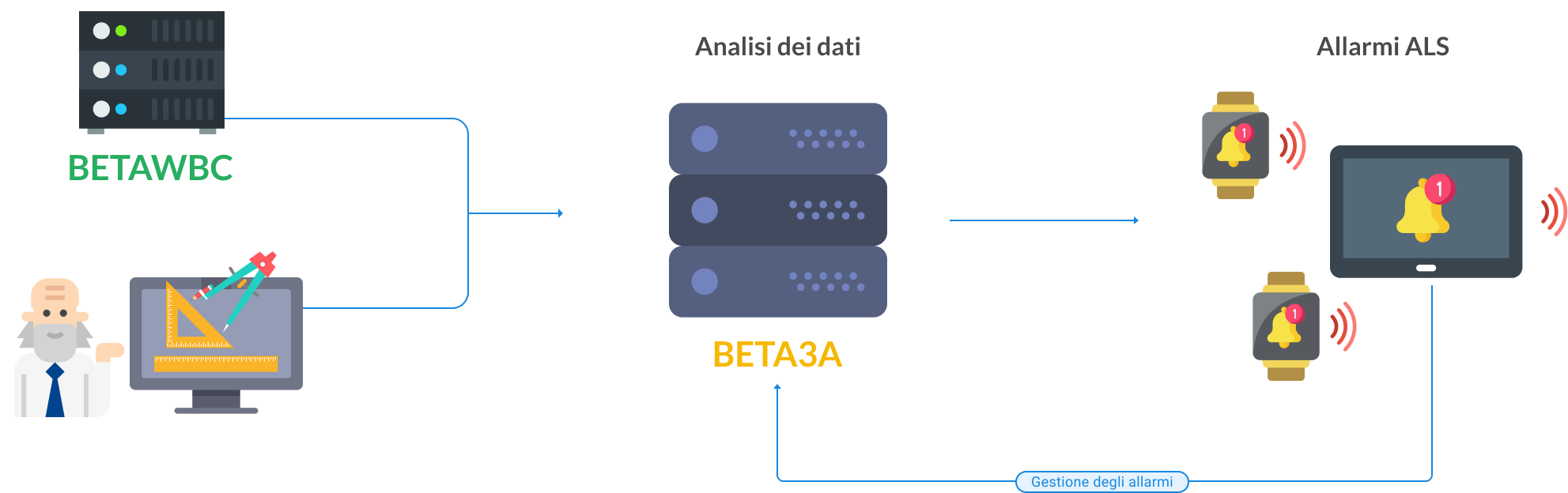

BETA3A (acronym for Betacom Anomaly Analysis and Alarms) is a software that manages anomalies on process components of a Production Line by sending real-time notifications. This enables defective components to be traced and withdrawn from the process.

BETA3A is a responsive, multi-platform web-based application, thus installable on different types of devices and operating systems. By setting the parameters of the process components, BETA3A allows data collection from analysis laboratories and BETAWBC (Beta Weld Bead Control). Data are compared with previously configured parameters: if any of the values exceed pre-set thresholds, BETA3A sends operator warnings or generates events for external applications to intervene and block the station responsible for the problem. BETA3A can also activate a dichotomous rise.

Alarms are managed by the ALS (Alarm System) component and displayed on smart watches and Android tablets, PCs, from which they can also be managed.

WEB SERVER-CLIENT APPLICATION

REAL-TIME NOTIFICATIONS ON THE PRODUCTION LINE

ALARM STATUSES

GREEN

Process component measurements are correct and therefore in the positive range. Data are saved and no events or warnings are created.

YELLOW

Process component measurements are partially out of range but not critical. A warning alarm is sent.

BLUE

The process component measurements are partially out of range. The BETAWBC station sends n negative events that have occurred in the last 8 hours.

RED

The process component measurements are in a critical range and far from the standard measurements. An alarm and stop event is sent.

Strengths

Multi-device and touchscreen

Featuring responsive web technology, BETA3A is optimised to be used on PC and mobile devices such as Android tablets and Android Wear OS smart watches.

Lean technology

By using lean technologies such as Node.js on the server side and AngularJS on the client side, BETA3A is a very lightweight application and does not require high computational resources.

Sending notifications and alerts

Two types of alerts can be identified: blocking and non-blocking. Blocking alarms are urgent and can stop the production process, while non-blocking alarms are non-urgent but warn of a possible issue that needs to be fixed before it becomes a blocking one.

Measurement input

BETA3A allows you to receive measurements from bead analysis and compare them with pre-set configurations set by application administrators. In addition, BETA3A can be integrated with BETAWBC to receive bead analysis measurements.

Start and stop

BETA3A sends an HTTP event to an external application that can be used to communicate to a PLC to START/STOP the production process.

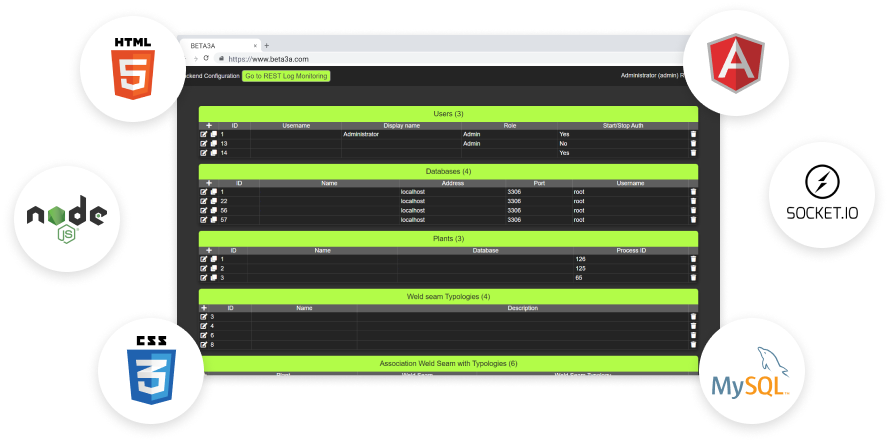

DEVELOPED WITH THE BEST TECHNOLOGIES

FRONTEND

The AngularJS framework, CSS3 and HTML5 were used for the configuration frontend. The interface is responsive and therefore adapts to any type of device. Through the use of Socket.IO the data displayed is updated in real time.

BACKEND

The server uses Node.js and relies on a relational database Oracle MySQL in order to configure the application and save the process data. BETA3A is multi-database, i.e. it can read from several databases at the same time.

MORE INFO?

Or do you need a tailor-made solution?

More about our software.

We will be happy to advise you on the most suitable solutions for your company’s needs, answering any doubts or questions, or scheduling a guided demo to show you the functioning of our software.

We provide our services throughout the country.

Betacom staff is at your disposal:

fill in the form and we will contact you.