BETAWBC

Visual inspection and repair system for process control.

WHAT IS BETAWBC?

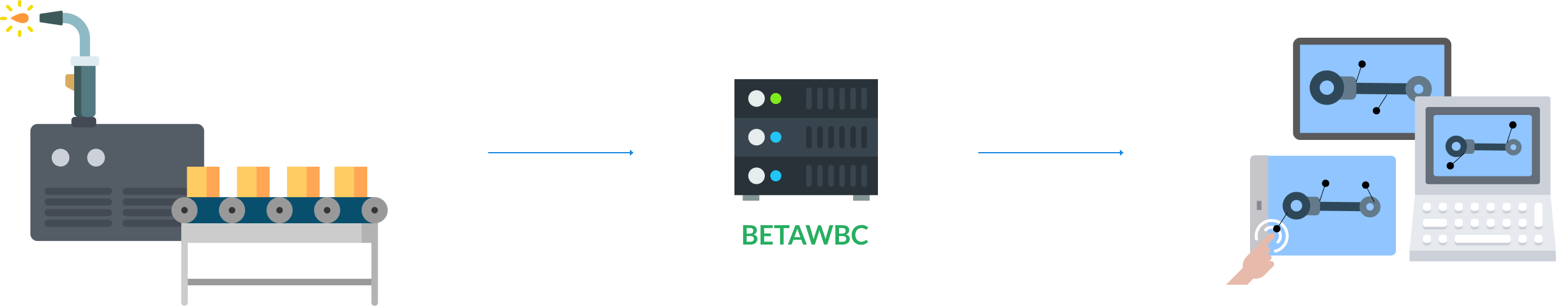

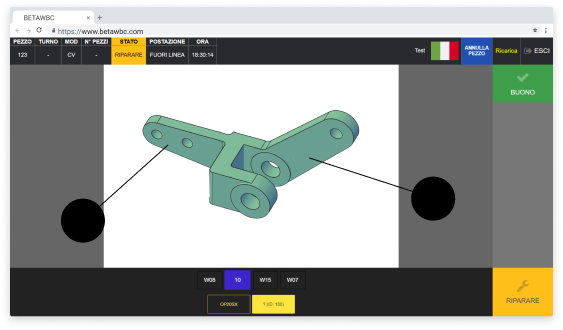

BETAWBC (acronym for Betacom Weld Bead Control) is a software for visual inspection and process component repair. The operator in charge of bead visual inspection can use a touch screen interface to set the outcome of a piece and define it as good, or define defective pieces and send them for repair or waste. BETAWBC is a multi-platform client-server web application that can be easily installed and setup on different types of devices and operating systems.

The work pieces to be analysed are identified by barcode or by events generated by the PLC. The operator sets the defective beads through the interface of the BETAWBC station using images of the part. There can be several contiguous visual inspection and repair stations or visual inspection only. All stations can be setup via the back-office interface that is accessible by means of credentials from an authorised administrator user.

MULTI-PLATFORM CLIENT-SERVER WEB

NO INSTALLATION REQUIRED ON EACH MACHINE

Strengths

Multi-device and touchscreen

Thanks to responsive web technology, BETAWBC is optimised for mobile use. The system is multi-platform and can run on Microsoft Internet Explorer or Google Chrome browsers.

Lean technology

BETAWBC is a lightweight application that does not require high computational resources, as it uses lean technologies such as Node.js on the server side and AngularJS on the client side.

Detection and correction of errors

It enables the identification of defective points, giving the possibility to repair or reject the manufactured part.

Interacts with the production line

BETAWBC stations can read work pieces via TCP/IP barcode readers or directly from PLCs using standard protocols. The result or further information of the work piece can be returned to the PLC and thus to the production process.

External interactions

Through HTTP POST requests, BETAWBC can send the result of the work piece to external applications which are compatible with the HTTP protocol.

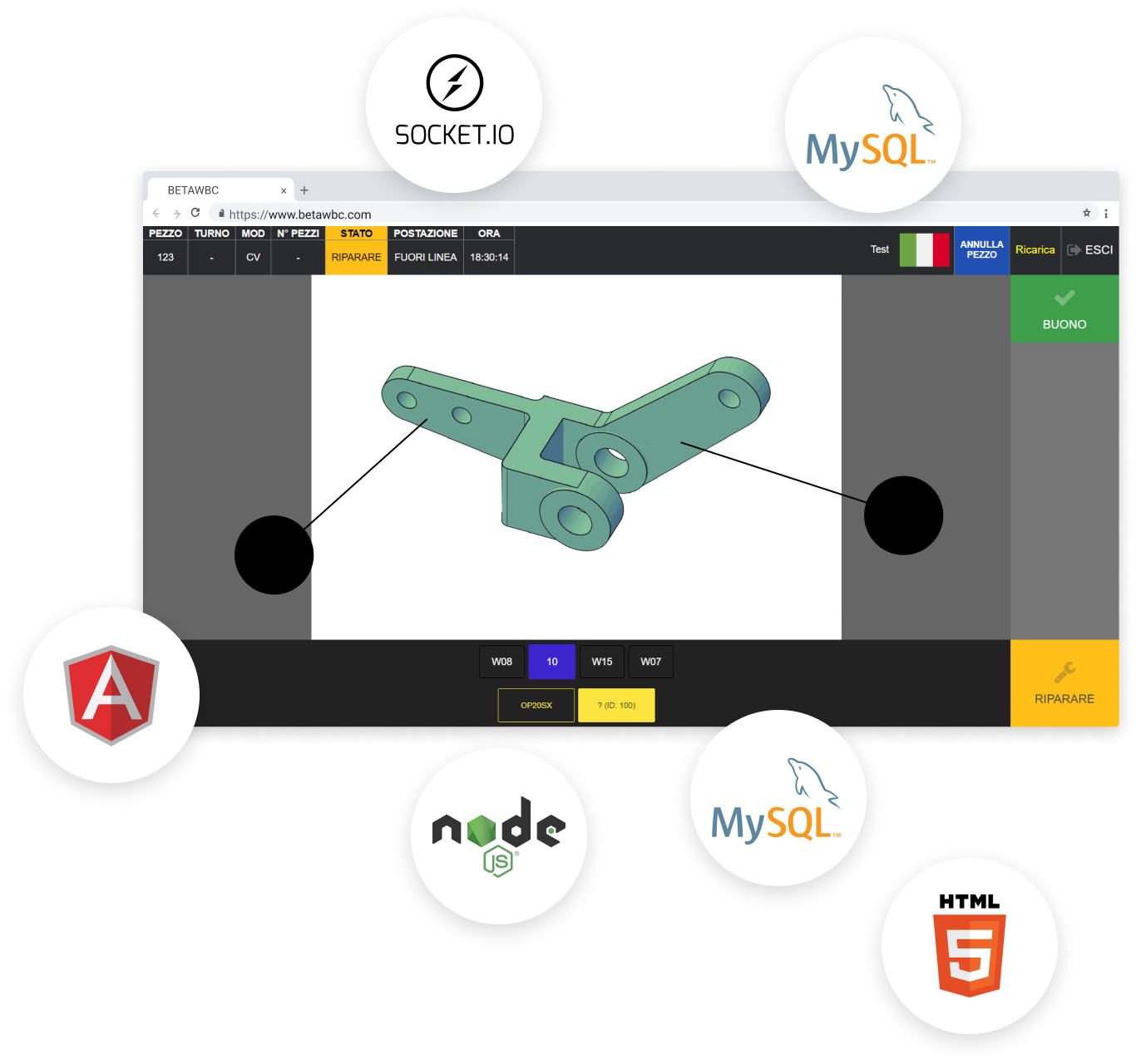

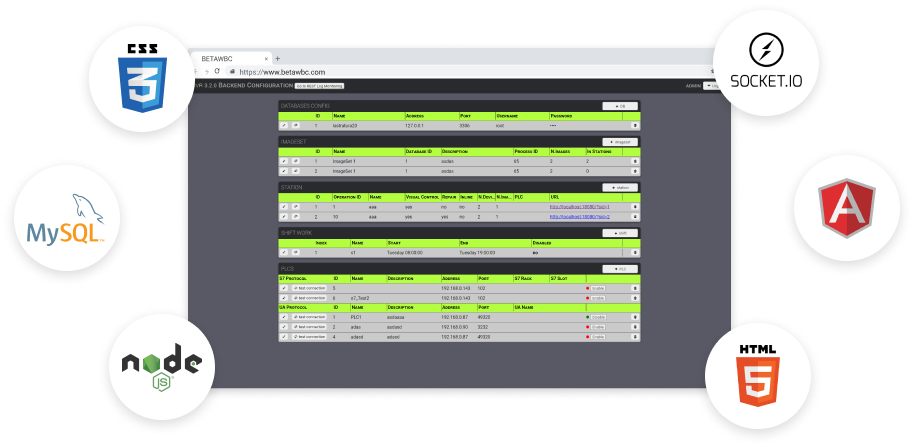

ENGINEERED WITH THE BEST TECHNOLOGY

FRONTEND

The AngularJS framework, CSS3 and HTML5 were used for the configuration frontend. The interface is responsive and therefore adapts to any type of device. Through the use of the TCP protocol, it allows the configuration of TCP/IP barcode readers.

BACKEND

The server uses Node.js and relies on a relational Oracle MySQL database in order to setup the application and save process data. BETAWBC is multi-database, i.e. it can read from several databases at the same time.

MORE INFO?

Or do you need a tailor-made solution?

More about our software.

We will be happy to advise you on the most suitable solutions for your company’s needs, answering any doubts or questions, or scheduling a guided demo to show you the functioning of our software.

We provide our services throughout the country.

Betacom staff is at your disposal:

fill in the form and we will contact you.